Well, it only took three years to get this rifle where I want it! It started it’s life as a model 112, stainless single shot in 300 Win Mag. I was building it for 300 and 500 yd Egg Shoots we hold at my local club, plus I’d take it out to Montana for 1000yd PD shoots.

The barrel was the original flutted stainless barrel under a 6061 Aluminum shroud. The muzzle was threaded for the muzzle brake/tension device.

As a 300WM it shot OK, but not great. Three into one hole and then a couple fliers. For no reason, other than something to do, I chambered it to 300 Ultra Mag. This chambering shot terrible. It would have been fine for a hunting rifle, as it shot under 1″ all day long, but not good enough for eggs.

Since our Egg Shoots require a “Factory” rifle to have a factory barrel and believe it or not, at the time, this rifle would be considered factory, as we “shoot barrels against barrels”) I sourced a 243 stainless fluted barrel from the internet and chambered it to 6mm Ackley. This combination shot GREAT! Five shots under 3/4″ at 200 yds all day long! With a factory barrel………But a few of the boys suggested that I might be pushing the rules a wee bit to shoot this “thing” against stock Remingtons and Savages…….I had to agree.

So since I would now be shooting against the likes of Kreiger, PacNor and Shilen, I ordered up a brand new Kreiger 6mm barrel and converted it once again……This time I wasn’t going to experiment with cartridges. I’m going for the win! So I went with a 6BR chambering………..Tried and true…..No muss, no fuss!

The rifle shoots amazingly well as a 6BR. With 31.5g of Vit-135 under any 65 gr Moly FB bullet, I’m getting one hole groups at 100 and under 1/2 at 200yds!

The rifle rides the bags better than any rifle I have at the moment………….

I’m not sure why it shoots so well, or if I had simply rebarreled using the Kreiger if I’d get the same results but I think there are some things in play here……

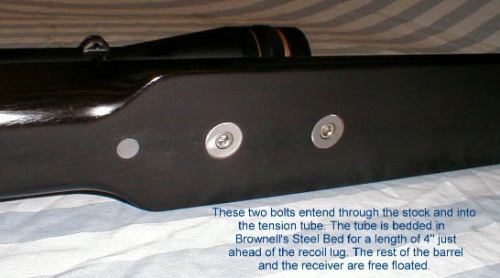

#1…The bedding….The action totally floats. From the recoild lug back, nothing touches the stock. The tension tube is the only thing touching the stock. Very sinilar to a barrel block.

#2….No heat mirage off the barrel. You’d have to do an aweful lot of sustained firing to get the tube to heat up any.

#3….The barrel nut/muzzle brake is tightened and loosened to tension the barrel. I believe this acts as a barrel tuner.

Changing the tension absolutely moves the point of impact. Accuracy can be tweaked a bit, but the rifle shoots any weight bullet at any velocity with the same accuracy.

It is no longer “Load /Seating Depth/Bullet Type Dependent”

I’m convinced that a tension barrel removes most of the harmonic effect on the rifles accuracy. (or inaccuracy)

I’ve now been using this rifle out in Missouri and other places for long range shooting and it simply keeps on “Keeping On”!

Fantastic accuracy and near no recoil. You can easily see the bullet impact the target…

On to the next project!

2 comments on “RIFLE TENSION BARREL PROJECT”