Brass is an interesting alloy. It is perfect for use in firearms cartridges because it expands easily upon firing to seal the breach of the firearm so no hot gases come back toward the shooter and then it immediately contracts so the empty brass cases can easily be withdrawn from the firearm. Poor General Custer at the battle of Little Big Horn had copper cased ammunition. Copper swells to seal the chamber, but under certain conditions will not contract to be easily removed. Many weapons were found lying next to brave deceased soldiers with a copper case stuck in the chamber. Soon after, brass became the only cartridge material for over 150 years. (You will find steel and aluminum cases for some types of weapons, but it is not reloadable and therefore not seen except for plinking and used by folks that don’t reload their ammo.)

One problem with brass for the person who reloads their own ammunition is work and or fire hardening. Brass needs to have a certain “softness” for it to work properly. After firing a case and reloading it a number of times, the bras becomes “work” hardened and brittle. It no longer holds the bullet the way it did when the brass was new and this leads to inaccuracy or what is called “case splits” where the brass case actually splits and needs to be discarded. If the cases are properly annealed, they can be reloaded dozens of times with very little loss of accuracy or damaged brass.

Do a search on the internet for Brass Case Annealing and you had better have days available to read all the methods folks are using. Some “How Tos” show methods that simply will not anneal anything and other sites show technique that is down right dangerous as it is annealing the brass to a much to soft condition. Don’t forget, that little piece of brass is what stands between you and 50,000 to 65,000 pounds of pressure in the chamber when the trigger is pulled. Later on I’ll show how to use a product called TEMPLAC to be sure you are annealing your brass at just the right temperature.

The best way to anneal brass is with some type of machine that consistently holds the brass in a flame for exactly the proper amount of time. There are Brass Annealing Machines available from a number of sources. (Google is your friend!) But they cost upwards of $500. I, like many reloading hobbyists, like to make some of the tools we use in this sport. An annealing machine is not beyond the ability of a serious hobbyist.

To complete this project in the way I did, you will need a small lathe. And a drill press or a milling machine would not be a bad thing to have either.

Let’s start right off with the concept.

Your brass is placed in holes cut into a steel disc. A small motor turns an arm that indexes the disc to move the brass into the flame of two propane torches. Once the brass has spent the proper amount of time in the flame to anneal, it is then deposited into some type of metal pan or container to cool.

I shot a quick video showing the actual moving of the disc and the brass movement. I’ve not installed the torches yet. I’ll add to this article when that part of the project is completed.

As you can see, it is really quite simple……

The disc used for this machine is available from a machine shop on the internet, J Morris.

Here is a You Tube video of a completed machine he built:

http://www.youtube.com/watch?v=CWCNoFDCdLA

This thread from the “Cast Bullets Forum” has lots of info and a way of contacting J Morris for a disc and current pricing.

So, on to my build.

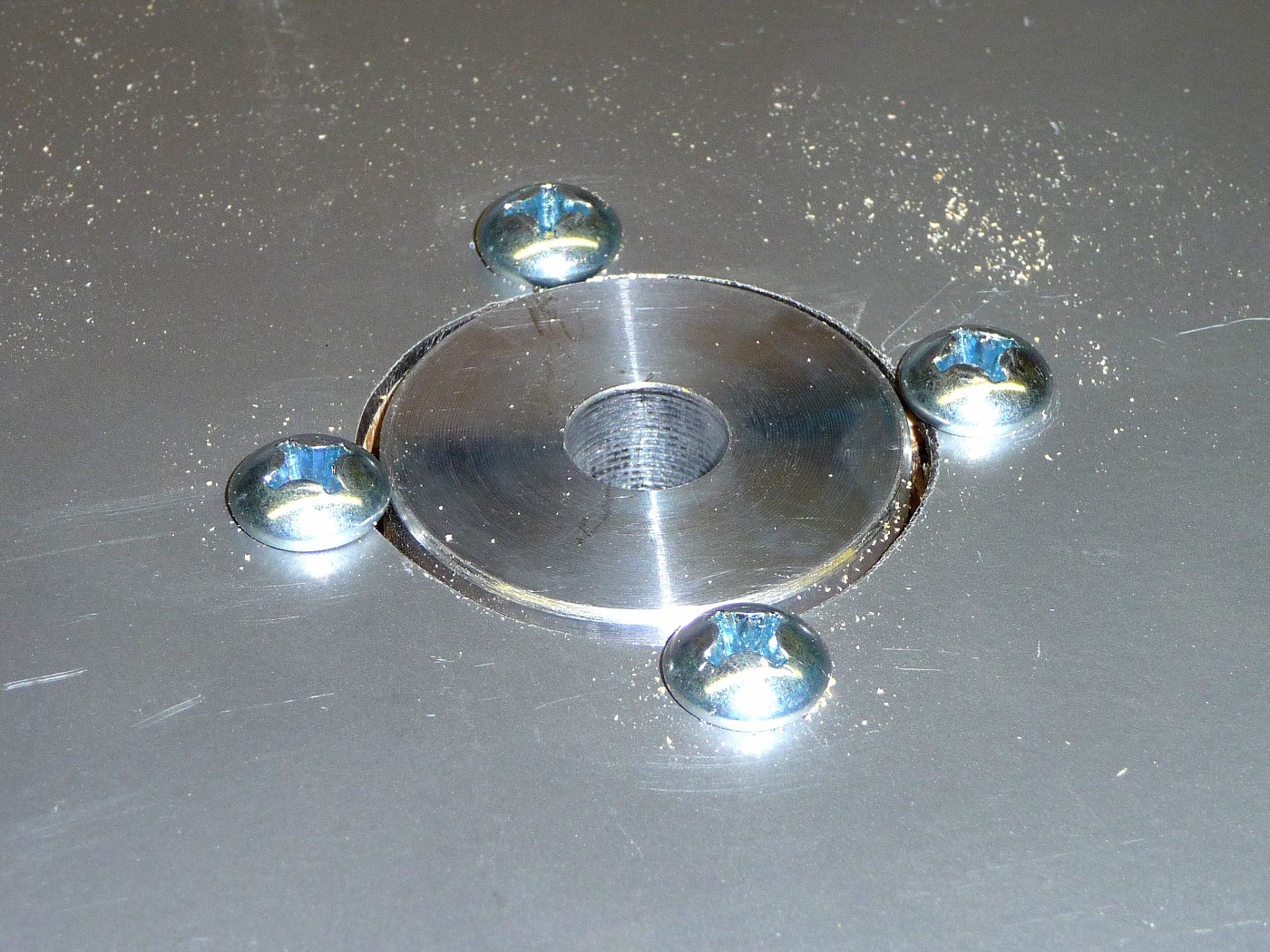

First thing I did was put a 2.5″ diameter by 3″ length piece of aluminum in the lathe and turned a huge bearing for the disc’s shaft to ride in.

This piece was stepped so a 1.5″ piece extended to the top of the machine and this left a 1/2″ shoulder that was drilled and tapped for four 1/4-20 bolts

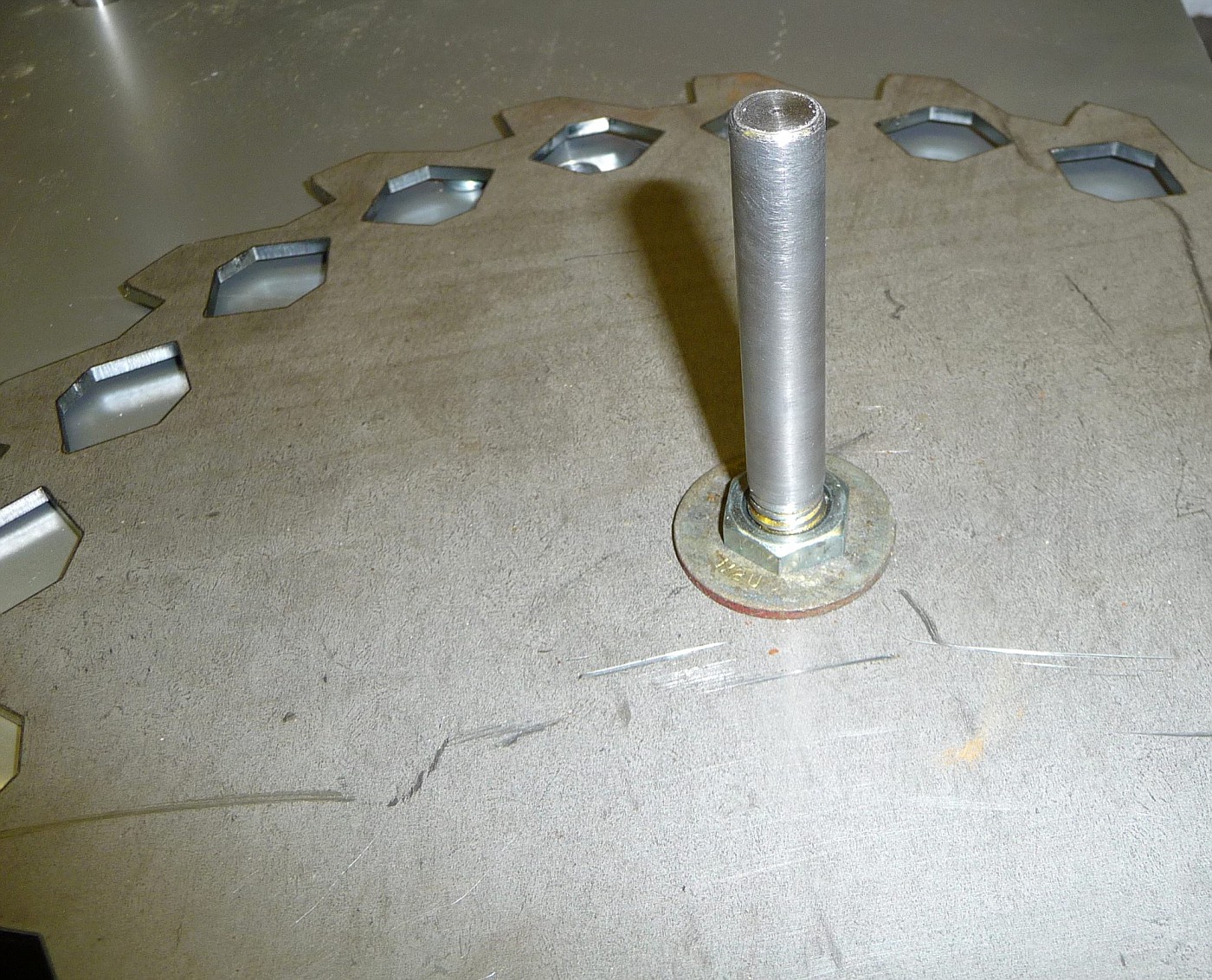

A hole of just under1/2″ diameter was drilled to a depth of 2.75″ and a shaft was turned for a very tight slip fit and then threaded on one end for 1/2″ course nuts.

This disc is not actually spinning, it is simply advancing a degree or two at a time. I’m not concerned about needing a sophisticated bearing for this use. The hole in my bearing was not drilled all the way through. Some “Mobil 1” synthetic oil and it make a nice “oil bath” bearing. If I spin the plate it revolved for minutes! Very little friction.

THE MOTOR:

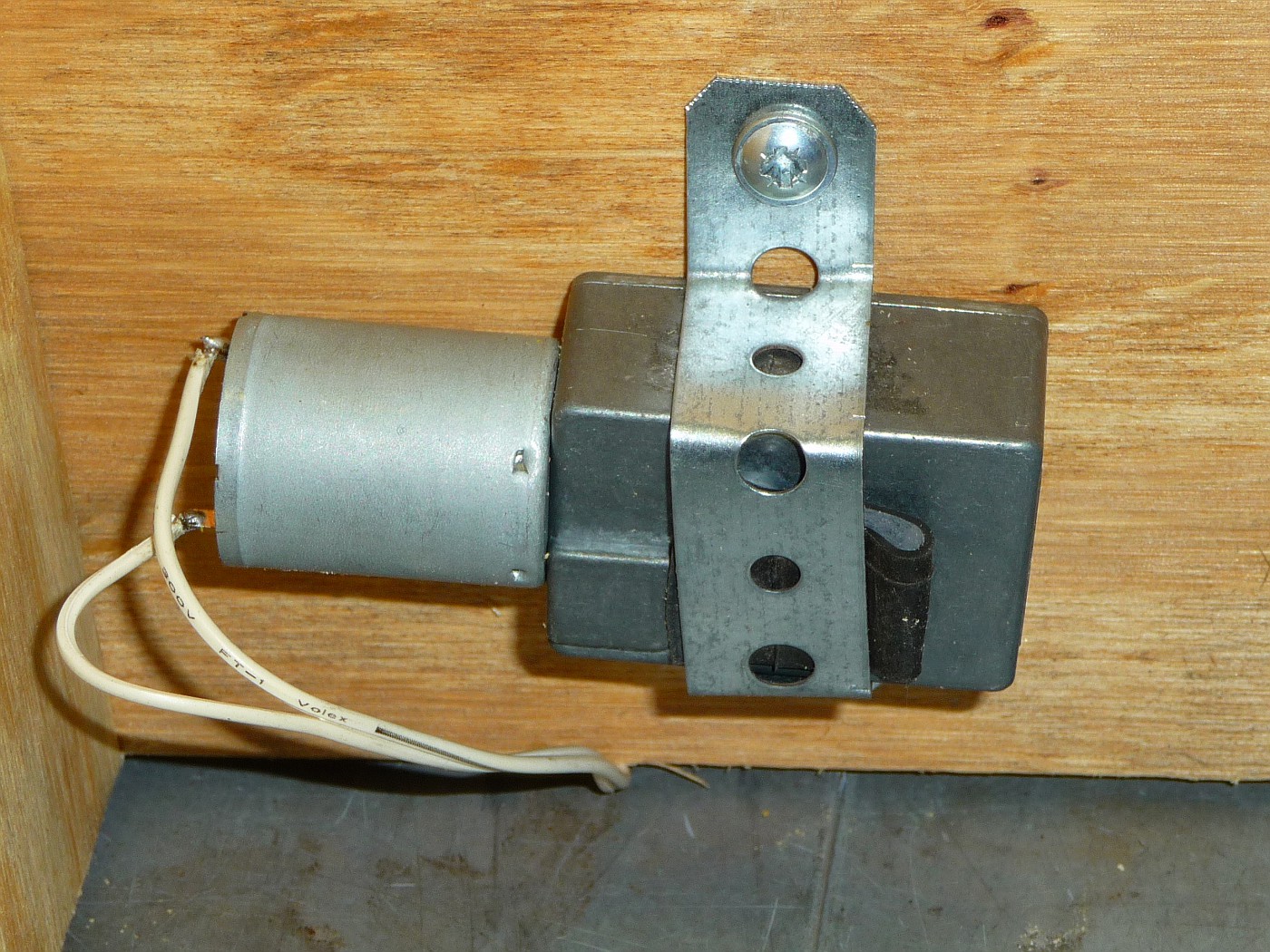

The best motor for the job is a Dayton 2L009 12V Gear Motor with 17RPMs. About $50 from many internet vendors.

I had a small 24rpm , 12V gear motor hanging around so I used it. I think I paid under $10 for is a couple years ago from eBay. You need a motor that turns at around 20 rpms. (update: I see this motor is available from AMAZON

http://www.amazon.com/Amico-6mmx14mm-Connecting-Electric-Geared/dp/B00EDMIAU8     and from a company called UXCELL   http://www.uxcell.com/12v-830024rpm-6mmx14mm-shaft-pins-connecting-electric-power-geared-motor-p-416211.html    and the price is $17 – $19, depending on whom you source it from, as of this writing 1-12-14)

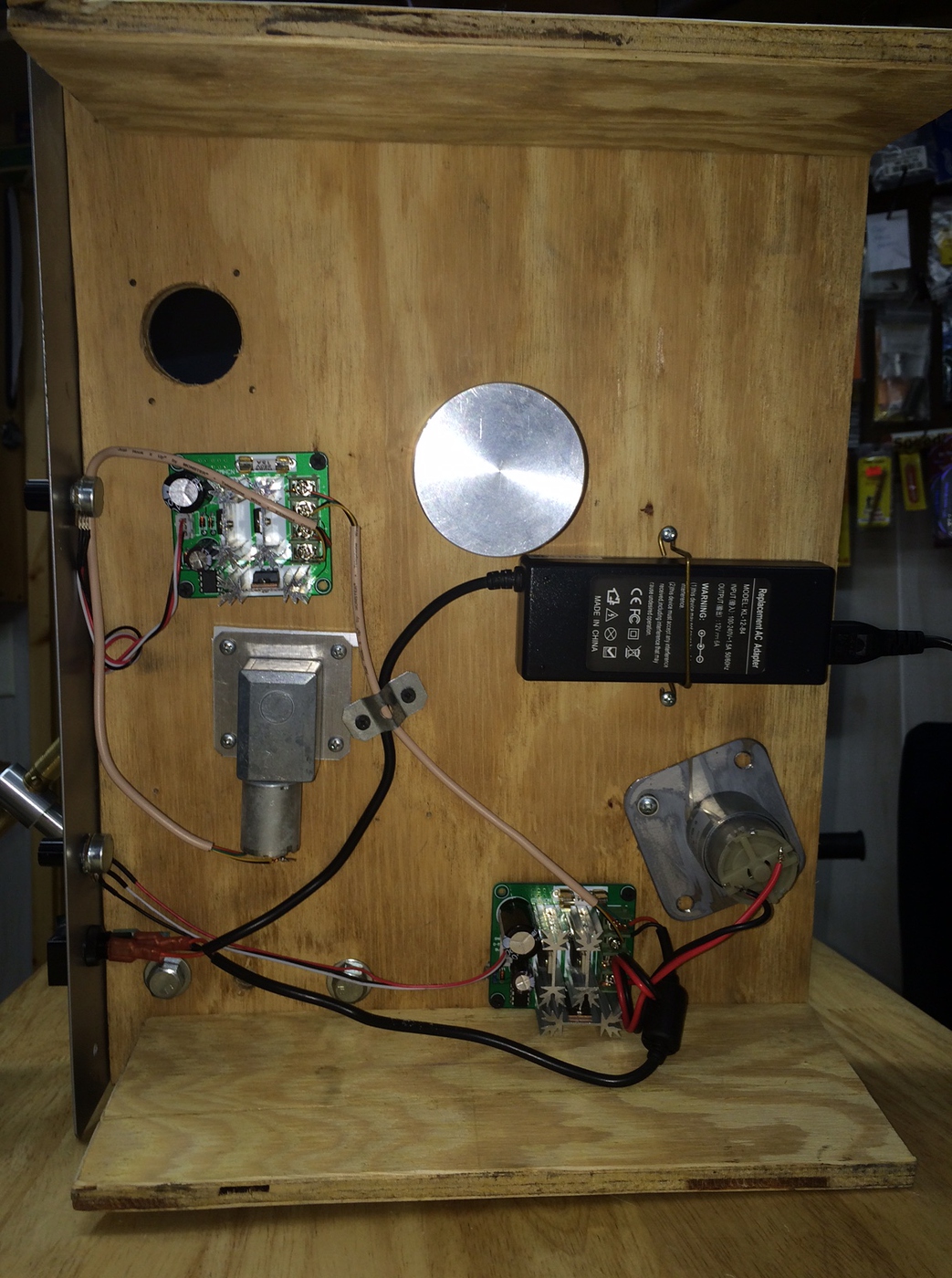

I made a simple bracket to mount it from the bottom of the machines main surface.

UPDATE 1-25-15….I recently replaced the above motor with this one. I needed a motor that spun just a bit faster.

RioRand 30RPM Mini Gear Box Electric Motor 12V DC 37MM High Torque

Just a few RPM faster as the plate was spinning a bit too slow for the very thin 38-40 brass I wanted to anneal

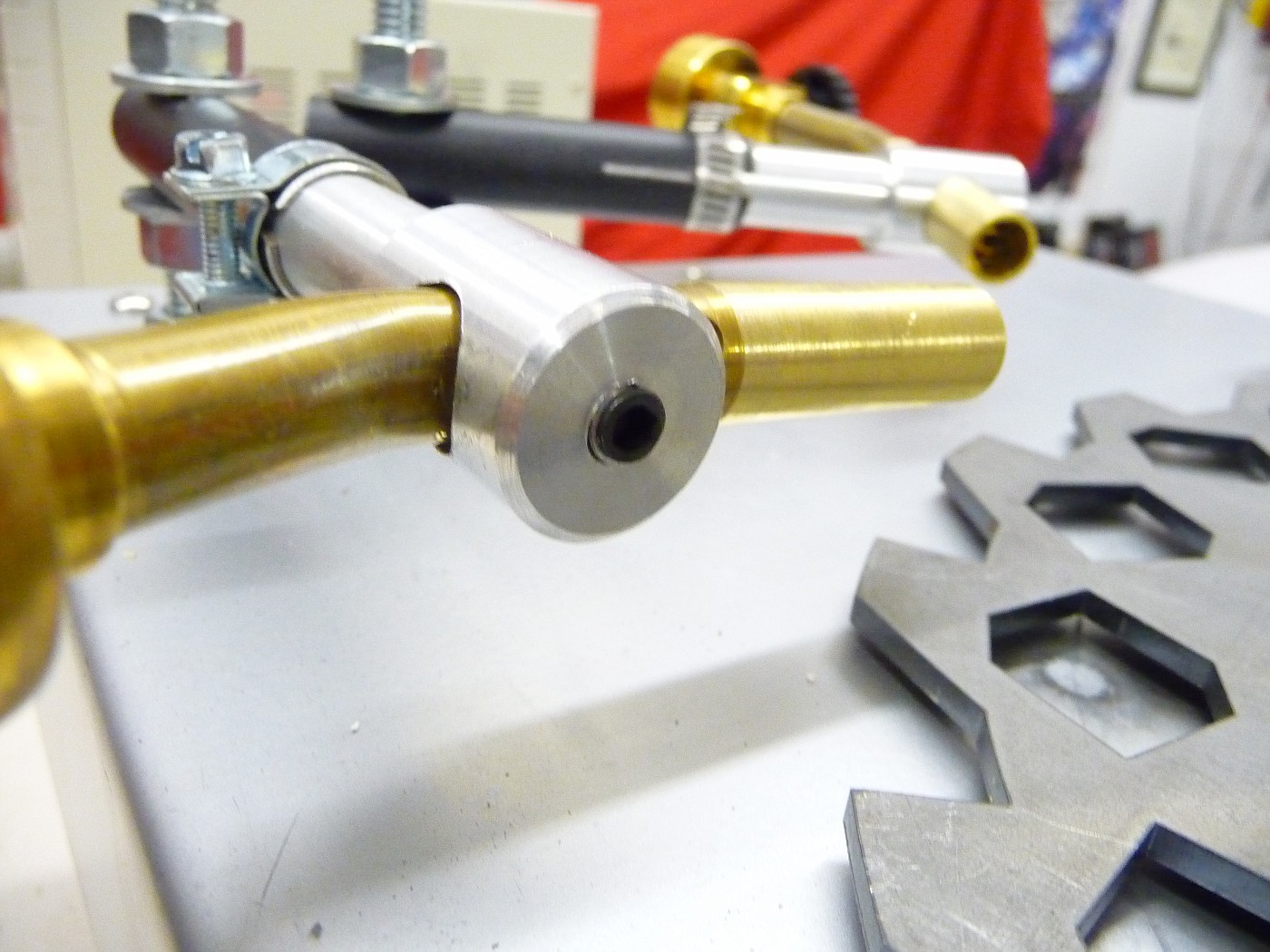

Back to the lathe, I turned, drilled and tapped a few pieces of solid aluminum round stock to make up the arm that advances the plate.

I’ll detail the assembly of this piece with better photos later.

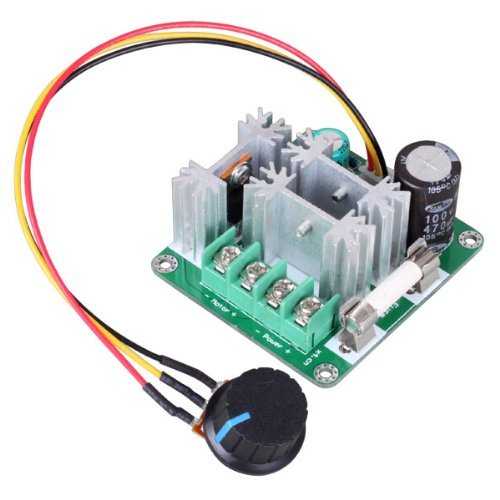

To control the speed of the motor, and therefore how long the brass remains in the flame, I have access to a DC Variable Power Supply.

But a simple rheostat of the proper type and size for your motor would be just as good. All you need is the ability to slow down the motor so the brass remains in the flame the appropriate amount of time.

UPDATE 1-25-15………..I added a simple power supply and a SCR variable speed control. No need for the bulky power supply now.

RioRand Upgraded RRCCM6NSPC 150W 6V 12V 24V Reversing Switch Adjustable DC Motor Speed Controller PWM

Power Supply:

12v 6a Adapter Power Supply for a computer LCD Monitor with Power Cord

A hole is drilled into the base so the brass can fall free as shown in the video.

I built my annealing machine out of scrap plywood and a piece of metal I had laying around the shop. Folks have built them totally of wood and others have welded the platform of steel. If you use wood, I’d cover it with some type of metal as I’m sure with prolonged use the surface can get quite hot.

This article will be updated as the Annealing Machine nears completion and then a total “How To” on How To use the Brass Annealer Machine….

Stay Tuned!

UPDATE 1-11-14

FINISHED!!!!!

Finally found some time to finish the brass annealing machine.

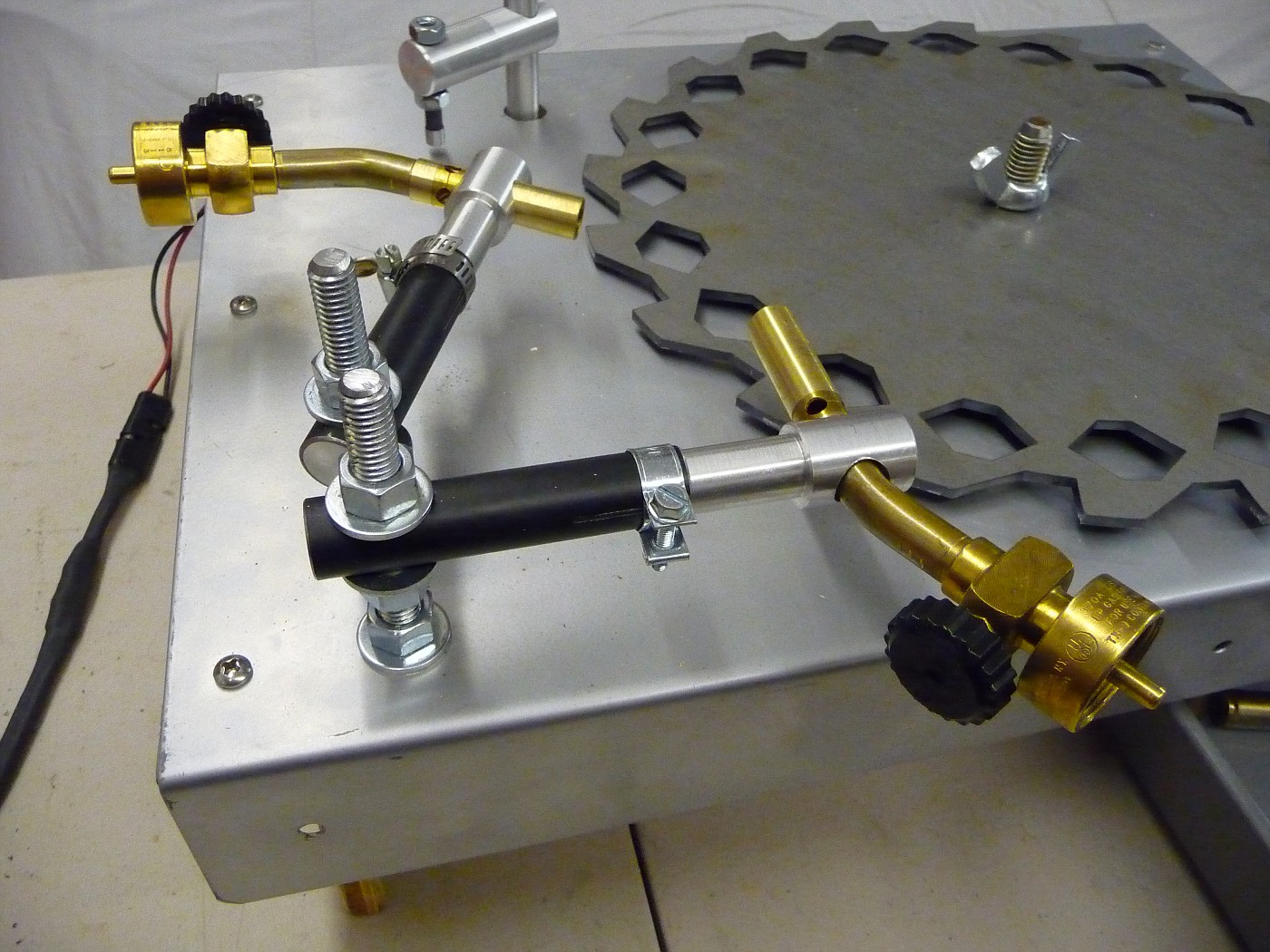

A couple of 3/8 X 4″ bolts served as the mounting posts:

I used some steel tubing I had in the shop and simply split it with a hack saw. A couple hose clamps secure the aluminum shafts I turned on my lathe:

Set screws secure the torches into the extensions.

The machine works great. I need to order some propane hoses and connectors to run the torches off a 20 pound propane cylinder.

Here is a quick video of the finished product:

UPDATE 1-12-14

J.MORRIS METALS contact information

Send me an email and I’ll send you J.Morris contact email address. I’d rather not post it here as I’m not sure how he is handling SPAM.

You can email me at       rvb100@comcast.net

My Propane Solution…..

I have one of those garages that if you look long enough you can find anything you need for any type of project!….:grin:

Looking through some old camping equipment I found a “Propane Tree”. This is a pole with three propane outlets for hooking up a camp lantern, cook stove and some other propane appliance.

I then found two propane hoses. One was a direct fit up…..Male disposable connector to female disposable connector.

The other hose had a connector on one end for the torch but the other was to be connected to a 20 pound cylinder. A bit more looking and I found a brand new adapter, in the bag! AMAZING!

Everything works great without having to disassemble the torches.

Thanks!

UPDATES 1-25-15

Installed power switch and the potentiometer for the speed controller:

Mounted SCR controller and the power supply under the unit:

UPDATE 10-25-15

Well…I found it difficult to quickly adjust the two propane torches as I changed from one type of brass to the other. And I also found it difficult to adjust the heat on the very thin necks of 38-40 and 44-40 brass that I use extensively in Cowboy Action Shooting.

I decided to add a second motor to spin the brass in the flame of a single torch.

I ordered another angle drive, gearhead motor like above and mounted it under the main chassis board in front of the torch. In this picture, it is the motor to the left With its motor speed control board above it.

Using a hole saw, I cut a hole in the chassis and on my lathe I turned an aluminum disc with a dished center. The dished center automatically centers the brass as it is deposited on this turntable.

I mounted a second potentiometer on the front of the chassis to control the “spin speed” of the brass. This new modification works MUCH better and the brass is much more consistently annealed. Success!

Here is a video of the machine working now:

http://public.fotki.com/Rbertalotto/gunsmithing-reloading/annealing-machine/annealing-img-0852.html

http://public.fotki.com/Rbertalotto/gunsmithing-reloading/annealing-machine/lights-off-img-0853.html

Thanks for looking!

UPDATE: Check out this very affordable, simple annealing ,machine I just discovered:

http://www.sageoutfitters.com/sage-annealing-machine.html

And this homemade machine is absolutely brilliant!

Pingback: Homemade case annealer. - Shooters Forum