One of the weakest points and an area prone to failure in the Colt Single Action Army and its accurate clones is the handspring.

The hand is the part connected to the hammer that when the hammer is cocked, it extends through a window in the frame and rotates the cylinder for the next round to be under the firing pin.

This “hand” uses a flat spring that is very thin and fragile. For the occasional SAA shooter it would probably last a lifetime. But if you shoot Cowboy Action, and put thousands of rounds through your revolvers, it’s not IF it will break, but WHEN will it break. Hopefully not during an important match. Don’t ask me how I know!

Here is a picture of a hand with an intact spring and a spring that broke off off another hand

Now if the hand spring in your SAA should break, you could simply order a new hand with an intact spring and swap the parts. But then it gets serious as you need to now time the hand so it doesn’t under or over rotate the cylinder. This is not a job for a novice. But it is a solution.

When RUGER reintroduced the SAA back in the 1950s they knew this was an area of concern. They went with a coil spring and a plunger in the frame to bear against the back of the hand.

If you have a good drill press or better yet a milling machine you can do this modification in under 20 minutes.

First, be sure the gun is unloaded. Check it twice!

Disassemble the revolver by removing the grip frame, the hammer and the trigger.

There are two screws that hold the grip frame to the main frame of the revolver. We are going to drill a small hole just above and to the right of the grip screw on the left.

In this photo just to the right of the black dot is where we will drill a hole.

You now need to figure out a way to secure the frame in your drill press / milling machine vise. I used a simple hardwood block and a C-Clamp

Be sure everything is level and the area you will be drilling is perpendicular to the drill bit.

Next use a spotting drill to indicate where the hole will be. The location is not that critical. Just center it above the screw hole and centered side to side.

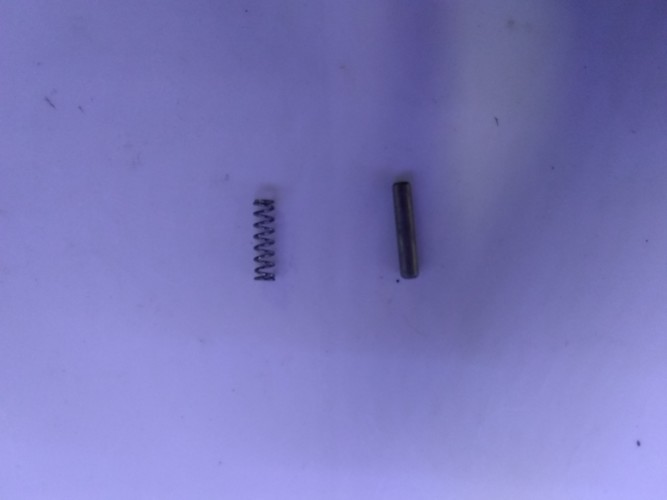

I used a .091″ drill as that is the diameter of the tiny springs I had in my junk drawer. I used a piece of a .091 drill bit as the plunger.

(Sorry, I didn’t measure the length of the plunger and the spring. The plunger was about 1/4″ and the spring about 3/16″……)

Drill the hole all the way through to the area the hand occupies.

Be sure to remove and metal chips and reassemble the revolver with the plunger first and then the spring, being held in place by the grip frame. The spring should be sticking out of the hole by about 1/8″ to 3/16″ depending on the length of your plunger and stiffness of the spring.

Put it all back together and on half cock, see if the “clicks” are there when the cylinder is turned. If not, your plunger/spring is too short. If the revolver won’t cycle and is jammed up, the plunger/spring is too long.

There you have it….Now just like a RUGER!

3 comments on “UBERTI SINGLE ACTION ARMY HAND SPRING FIX”