I have a horizontal bandsaw for cutting steel stock to length. It is an amazing time saver and a great asset if you do a lot of metal fabrication.

This type of saw can be used in the upright position to cut metal on a small table. But it is inconvieneient to convert to this position. I wanted an upright metal cutting bandsaw.

But MAN, are they expensive. Way too much $$ for a small home hobby shop. So I bought a small three wheel portable bandsaw and attempted to slow it down with an AC Speed Controller.

BAD IDEA! Â This thing had very little power and although I could cut thin aluminum and thin sheet metal, anything more and it would bog down. I sold it and bought a floor mounted, 14″ Woodworkers band saw fro Harbor Freight. At the time, with a coupon it cost me around $200.

But even on the lowest of its three speeds, it was too fast for thicker metals and it ate steel cutting blades.

So converting it to a DC motor with variable speed control was the way to go.

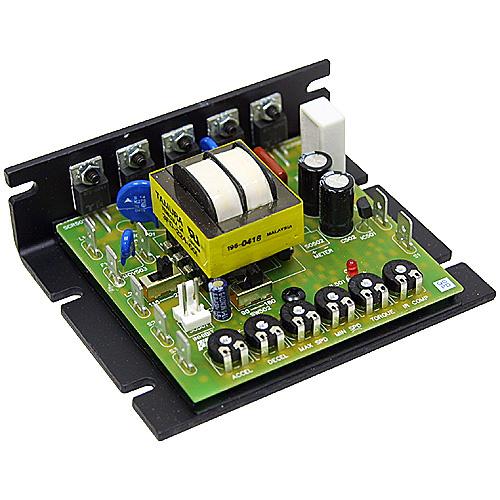

A few years ago, Surplus City offered “Tread Mill Motors” with control boards for $39.00 each. I bought a dozen of them and have used them on all kinds of woodworking equipment. They are great for this type of use. I figured I’d addapt one to the band saw also.

It was quite easy to replace the AC motor with this DC Treadmill motor.

I left the pulley system in place so I could manipulate the speed as I wished,

And I mounted the control board nearby:

The potentiometer was mounted on the front of the band saw:

A couple of simple paint brushes were brought into play to keep chips off the drive wheels:

New “Cool Blocks” were used to replace the plastic blade stabilizers

This was the way I used the saw for a number of years. But truth be told, the Tread Mill motor was not up to the task and stalled when cutting anything over 1/8″ steel. It needed ca better, stronger, motor.

I had converted my JET 12 X 36 BD lathe to DC drive using a Dayton, 90volt, 3/4hp motor with an SCR controller and it has been magnificent.

http://rvbprecision.com/garage-entertainment/metal-lathe-dc-motor-conversion-jet-12-x-36-bd.html

So the search was on for another DC, 90v, 3/4 HP motor.

Best price I could find was AMAZON.COM An AMARINE, 90v, 3/4hp motor was $179 including shipping. I ordered it on Friday and it was at my door on Saturday afternoon!

Permanent Magnet Dc Motor, 3/4hp, 56c, 90v/1750rpm

- Highest quality oriented magnets

- F insulation class

- CE listed, CE file No. DW2011CE0047 01

- 56C face and Removable mounting bases for dual mounting versatility

- Continuous duty; Dynamic balanced armature for smooth operation; Totally Enclosed Non Vent; Double seal ball bearings with permanent grease filling for long life; Long life brushes;

This new motor was even easier to install than the treadmill motor. All the mounting holes lined up perfectly.

I modified the mounting plate with a couple pieces of threaded rod to maintain constant pressure on the drive belt

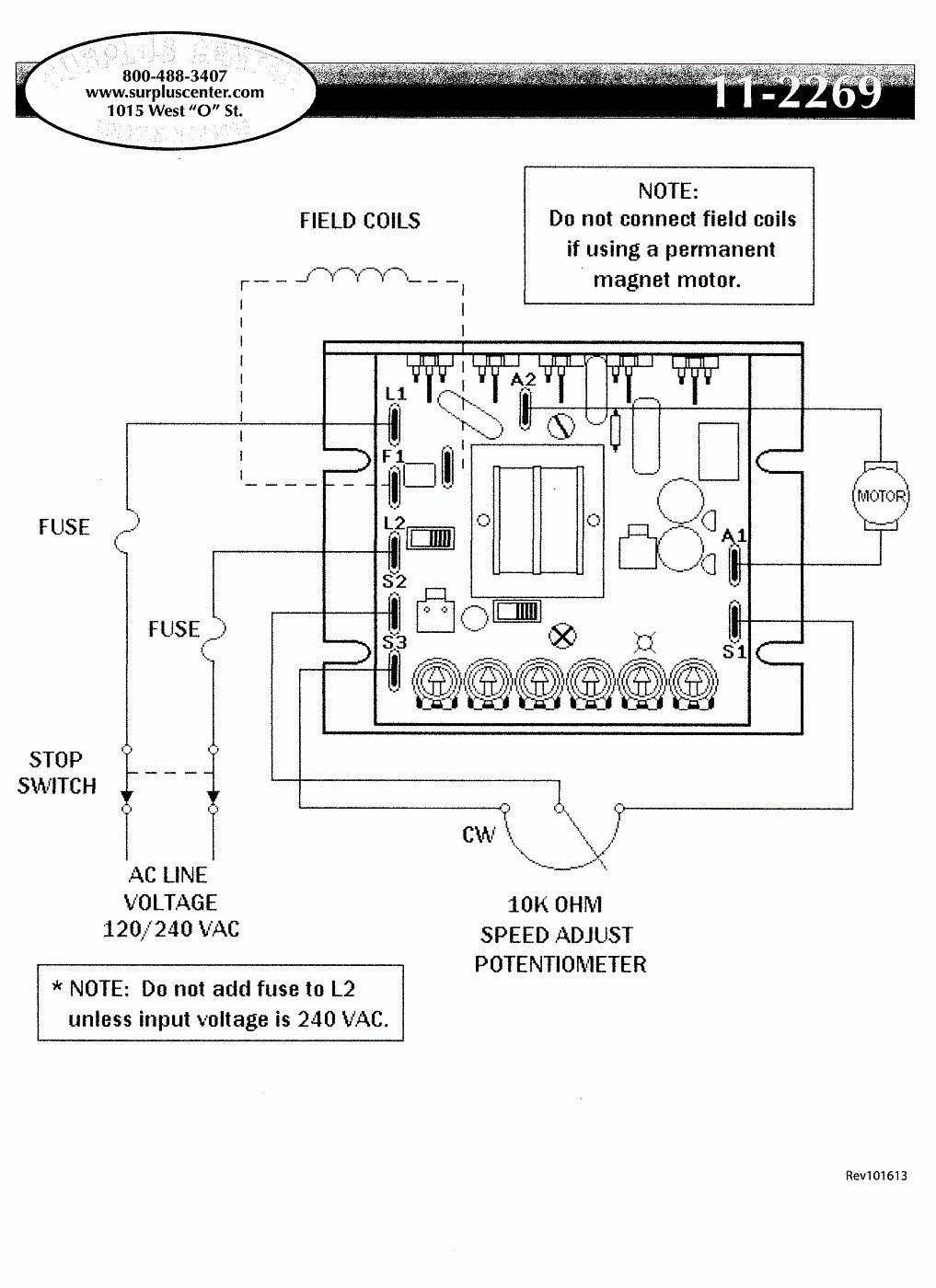

A new DC controller was needed. I turned to SURPLUS CENTER for a SCR board

This is a great controller that I also used on my lathe conversion

90/180 VDC SPEED CONTROL W/POT

ITEM NUMBER: 11-2269 Â Â Â Â Â Â Â Â Â Â PRICE: $81.95

Wiring was extremely easy.

This can also be found on the SURPLUS CENTER web site:

http://www.surpluscenter.com/_MoreSpecs/as11-2269.pdf

and here:

http://www.surpluscenter.com/_MoreSpecs/i11-2269.pdf

Â

Just to be nice, I gave the old gal a new speed control knob;

Here is a video showing the saw cutting metal:

http://public.fotki.com/Rbertalotto/machine_tool/bandsaw-wood-to-met/p1010001.html

Â

Also on YouTube:

Â

Hope you enjoyed this little article

Lots more here:

Â

Thanks for looking!

Â

UPDATE 12-14-20

There was a need to start cutting thicker material on the Bandsaw Conversion. Although the original conversion was fantastic for 1/8″ material or less, cutting 3/16″ up to 1/2″ material was a challenge.

I had the opportunity to purchase a Contact Tachometer from Ebay that also reads SFM. This allowed me to verify the actual SFM (Surface Feet per Minute). To my surprise I was three to four times faster than recommended.

https://www.sawblade.com/band-saw-blade-speed-and-feed-chart.cfm

This is a great resource to figure out your SFM of a bandsaw

http://vintagemachinery.org/math/sfpm.aspx

So I needed to slow it down more than the DC motor and pulleys allowed

A bit of research lead me back to Surplus Center and right angle gear reduction units.

I purchase a 50-1, left hand unit that had a 56C mounting option . This would mount directly to the DC motor I’m using. (See a picture of the motor above with the 56C mounting flange)

Â

Â

From the gear reducer I used a series a few different size pulleys, removing the idler pully to get down to somewhere around 200SFM

But there were issues with belt slippage. The motor never came close to stalling, but with a 50-1 gear reduction the output torque is enormous and the small pulleys needed to get the speed down did not afford enough “Pulley Wrap” to stop slipping.

Back to Surplus Center and an order for a couple chain drive sprockets and some 40 pitch chain….

A 17 Tooth sprocket on the bandsaw drive wheel and a 30 tooth sprocket on the gear reducer gave me 256 SFM with the DC motor on maximum speed. I can slow it down to 50 SFM and anything in between with the DC controller.

That did the trick!

Obviously, a chain ain’t gonna slip!

Now I have huge cutting power and the saw cuts through 3/8″ plate beautifully.

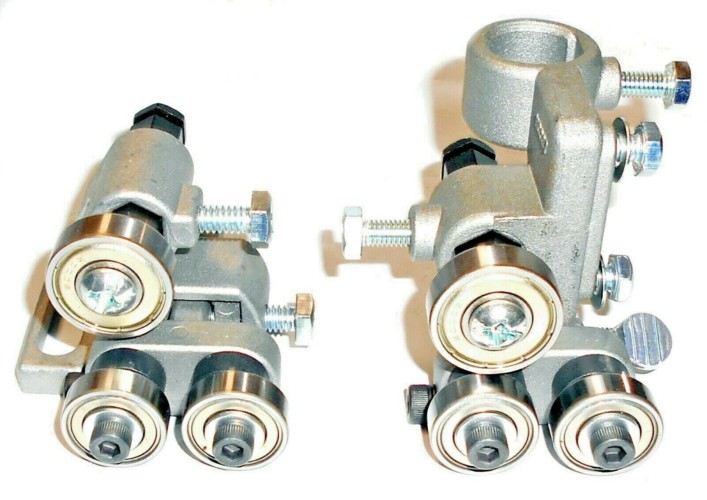

I also upgraded the entire blade alignment system with ball bearing blade guides that I found on Ebay. These made a huge difference in the accuracy of the cut. Much better than the simple guide blocks I had been using.

Hope this is of some help to those of you trying to cut metal with your wood bandsaw.

Be sure to check out other garage nonsense at www.rvbprecision.com

Thanks

11 comments on “Bandsaw conversion to DC drive…Wood to Metal Cutting Conversion”