I got involved in Cowboy Action Shooting (CAS) a couple years ago. As with most hobbies I get involved with, the equipment becomes just as much fun as the sport itself! I really enjoy the historical aspect of CAS and the “period correct” firearms that go along with it.

My first rifle for the sport was a Rossi copy of the Winchester 1892 lever action rifle. I bought this rifle in 45 Long Colt to match a set of Ruger New Model Vaquero revolvers I already owned. I soon found that although these Rossi rifles are a great bargain and extremely well built, being an 1892 design it was slowing me down with it’s very long lever throw.

Rossi 1892 Winchester / 45LC

Next up was a Uberti copy of the Winchester 1873. This rifle uses a toggle link mechanism and can be “Short Stroked” to really speed up your game. You can read all about short stoking one of these 1866/1873 Winchesters here.. http://rvbprecision.com/shooting/uberti-1866-winchester-short-stroke-install.html

Uberti / Winchester 1873 in 45LC

This is a fantastic rifle! Beautiful fit and finish and has an extremely high “fondle factor”!

But then something else happened. I discovered the fun of shooting Black Powder out of these firearms. To be totally “Period Correct”, you need to shoot Black Powder (BP).

The 45LC cartridge was originally a BP cartridge. It was used in Colt and others revolvers, but the 45LC was never chambered in a lever action rifle until 1973! This is a whole other subject for another time.

There is an issue when using the 45LC with BP in the light loads that CAS requires. When filled completely with BP, like it was back in the day, the brass case will expand nicely and keep all the nasty BP residue in the barrel and out of the action. Clean up is a snap as long as this residue doesn’t get in the action. But for CAS, you simply don’t want the recoil and power a full load of BP will give you. So you load the cartridges down and use fillers to make up the difference. Nice light loads, but they don’t seal the chamber properly.

So it was time for a look at a more “Period Correct” cartridge. This led me to the two cartridges that most of these lever action rifles were chambered for…. 38WCF and 44WCF. “WCF” stands for Winchester Center Fire. But when Marlin and others chambered their firearms for these cartridges, they didn’t want to use the Winchester name so they called them 38-40 and 44-40.

The 38-40 is on the left with a 45LC on the right. The 38-40 and 44-40 are bottle neck cases with extremely thin brass. This allows them to easily expand upon firing and seal the chamber keeping all the “junk” from the BP in the barrel and out of the action. Perfect!

So now I needed another rifle… 🙂

I searched and searched for a Uberti / Winchester 1866 in 38-40. Finally found on one the internet and had it shipped to my FFL here in town. The 1866 is an earlier model of the 1873. Both use the same Toggle Ling system so both can easily be Short Stroked.

I could have easily found this same rifle in 44-40 as that is a much more popular cartridge for CAS. But I had already been buying vintage rifles and I started with the 38-40 so I simply wanted to stay with this chambering

1889 Marlin / 38-40

1873 Winchester / 38WCF

So now I’m deeply involved with a few lever action rifles in the wonderful 38-40 cartridge.

A few months ago I’m visiting one of my local gun shops and up on the wall he has a Taurus clone of a Colt Lightning in 45LC. The Colt Lightning was built by Colt to compete with the various lever action rifles of the day. But it was a very complicated firearm and compared to the much simpler lever action, it never was much competition.

Seems the shop had this rifle for quite a while as it was made available to me at a great price.

This is a beautiful pump action rifle with a tubular feed magazine, case colored receiver and walnut stock and forearm. Because the cartridge is only about an inch long, the stroke is extremely short and it seemed to me this would be a great rifle for CAS.

As soon as I got home, I ran a few patches through the bore, gave it a couple dabs of oil and grabbed a few of my 45LC reloads and headed for the range. The gun functioned fine and with round nose bullets it fed great, but every once in a while it would “hick-up” and fail to feed. This I felt I could resolve or it might simply work itself out after a few hundred rounds. But there was a much bigger issue.

Because the 45LC cartridge was not sealing the chamber properly, the blow-back was terrible. Hot gas and powder residue would blast me right in the face. If I didn’t have on shooting glasses, this might have been dangerous. I tried heavier loads and it worked much better, but now recoil and muzzle rise was not appropriate for CAS competition. To be totally safe shooting this rifle, you would need to wear a welders mask!

This rifle needed to be re-barreled to 38-40. The bottle neck case would feed much better as this is the cartridge these rifles were chambered for back in the 1800s. Once again, they were never chambered in 45LC.

So here we go!

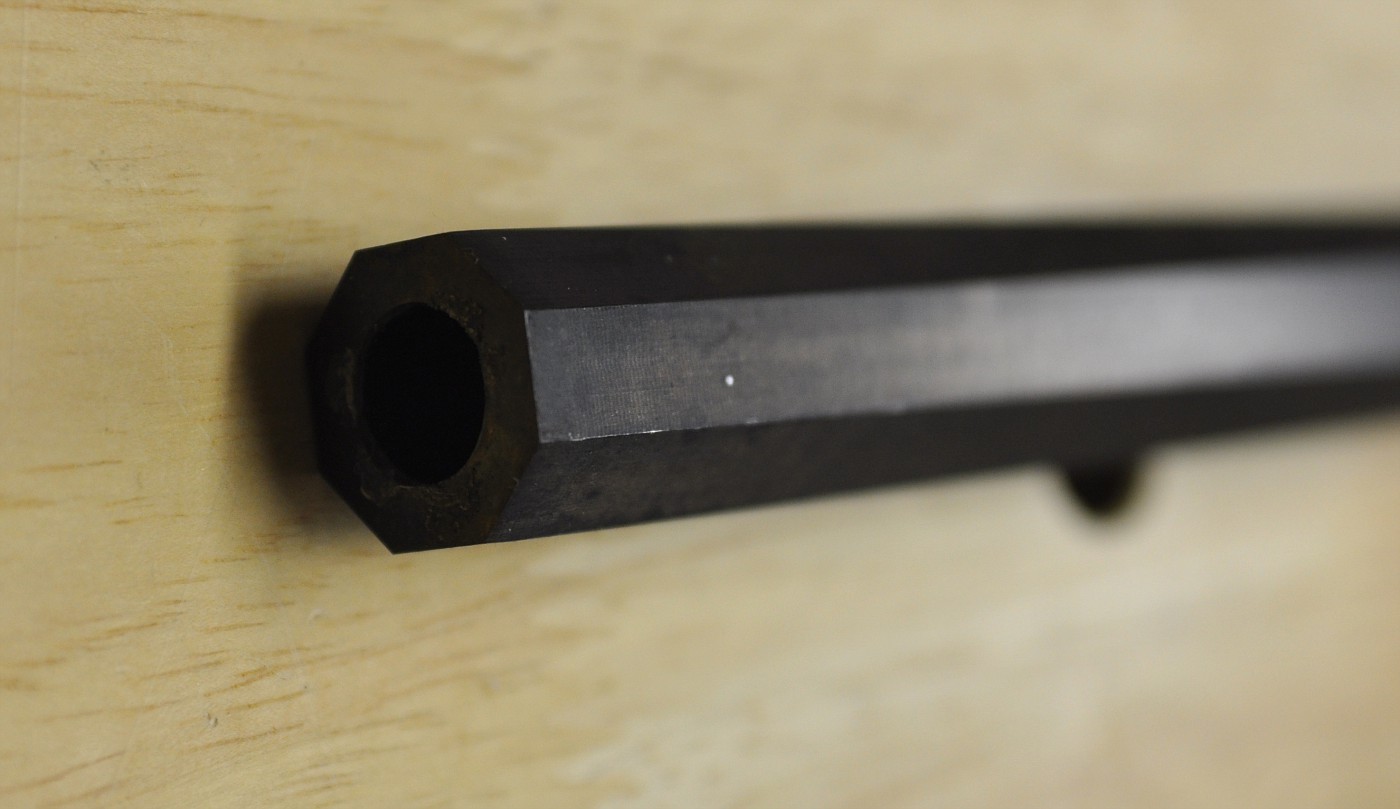

First order of business was to buy an appropriate barrel in 38-40 bore. I’m a total nut for octagon barrels so this rifle would wear ol’ Eight Side. Green Mountain Barrel Works makes a beautiful barrel so I ordered one up in 38 bore. (I know what those of you that know something about this stuff are saying…”The 38-40 is not a 38 caliber, it is a .401 caliber!”….You are correct! But for this article we will refer to it as 38.)

When the barrel arrived it was a thing of beauty!

The rifle was taken apart and the original round barrel was put into the barrel vice and removed from the action. I had to make a spacer to insert into the recess of the action so the action wrench would not crush the receiver.

The barrel was a bit hard to remove. I had to heat it up with a 1500 watt heat gun to break the “glue” that Taurus used on the threads.

So now the rifle is separated from the receiver and it’s time to thread and chamber the new barrel.

Another issue arose.

The threads on the Taurus barrel are metric. I’d never cut metric threads on my lathe. Twenty years ago when I bought this Jet 12X36BD lather, the previous owner had given me a box of gears and I remember him saying something about these gears are for metric threading. So I installed the appropriate gears and figured out how to thread in metric without using the half-nuts. Folks here on the internet were a great resource for this education.

Before I screwed up that nice new barrel, I chucked up a piece of scrap barrel and practiced threading in metric.

It was quite easy and came out great.

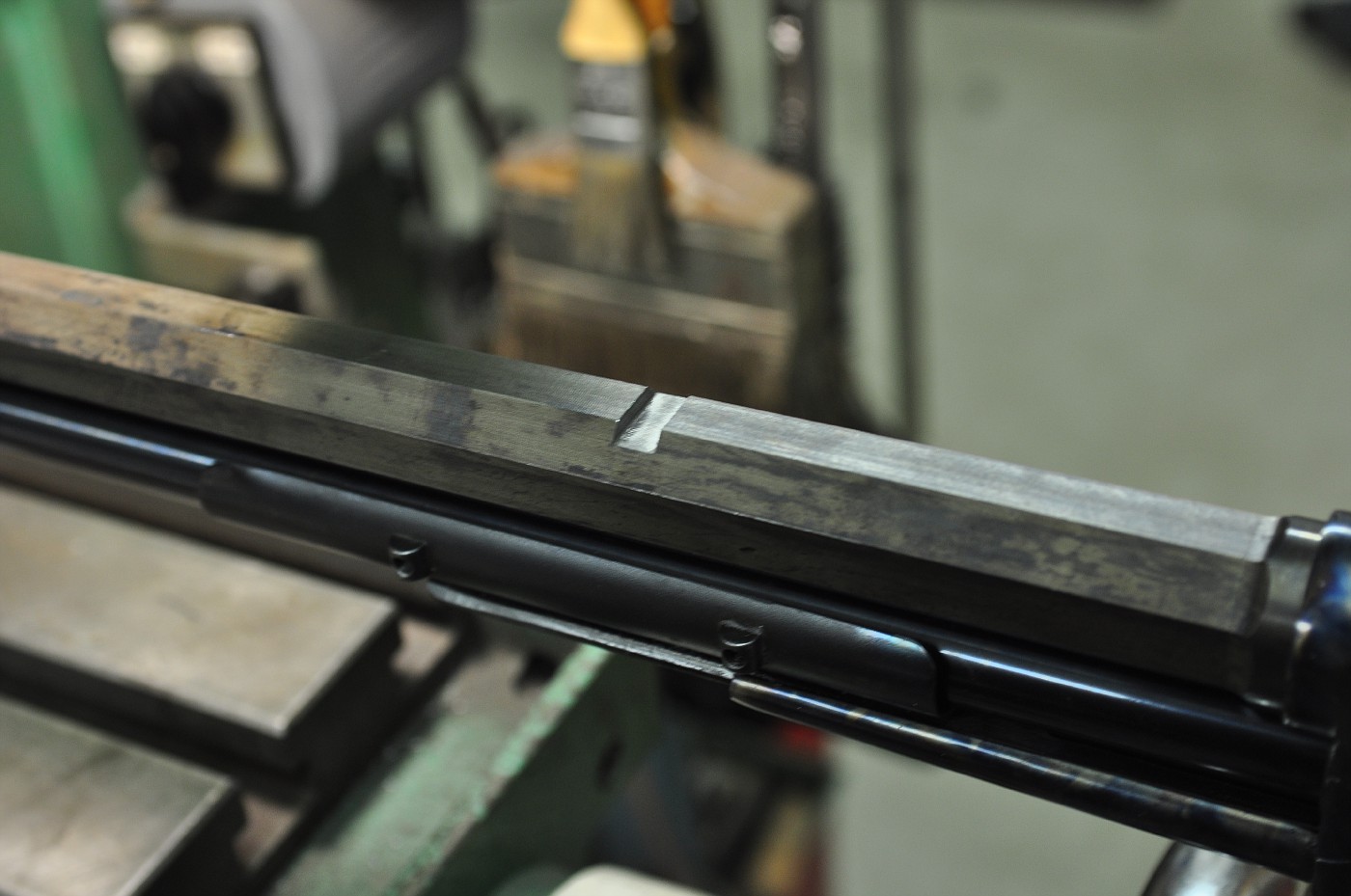

The new octagon barrel was installed in a four jaw chuck and turning and threading commenced.

Once the barrel was threaded and indexed so a “flat” was positioned on the top. the cuts for the extractor and the rim lifter were cut with a small wheel in a Dremel tool.

The feed ramp was ground and polished using a Dremel tool with a Cratex bit.

Here is a photo of the original feed ramp. Look how much material had to be removed for the big fat 45LC case to feed from the magazine.

And the factory chamber was extremely “proud”. This photo shows two layers of electrical tape on a 45LC case and there is still slop!

No wonder there was blow-back!

The barrel was turned around and cut to 22″ and the muzzle crowned.

The original barrel was 26″ and it was just too long and a bit unwieldy. Twenty-Two inches was just right!

Next it was over to the milling machine to cut the dovetails for the sights

I use the mill to hog out most of the material and then a special dove-tail file to finish.

Same for the rear sight.

The magazine tube was attached at the muzzle with a small threaded insert. The milling machine bored a flat bottom hole and the threaded insert was soldered in place. The original barrel used a dovetail with an insert for this and it didn’t look good in my eyes. Quite a bit of dove-tail was exposed on both sides and this would be exacerbated with an octagon barrel.

This design created a nice clean look, rather than using a dovetail.

The rifle was put back together and five dummy test cartridges were assembled without primers or powder. These cartridges were inserted into the magazine and the action was cycled as I held my breath!

It fed all five cartridges perfectly! No hick-ups, no issues. Beautiful! Ejected them right over my right shoulder……….Gotta Love It!

Off to the range…….A few cartridges were loaded single shot into the chamber to see if the gun held together. Worked perfectly. All fingers present and accounted for!

Ten rounds were loaded into the magazine and the action was cycled as fast as I could move it. No issues!

I’ve now fired over 500 rounds through this rifle with the new 38-40 barrel and it hasn’t failed to feed once. This rifle was designed for the bottleneck cartridges and this superb performance proved it.

I gave the barrel a very light bead blasting and cold blued for now. I’m not sure what the final finish will be. Some folks suggest antiquing it, other a nice rust blue and other a hot gloss blue. Rust blue is getting my attention currently!

That’s it! Hope you enjoyed this little article.

7 comments on “COLT LIGHTNING (Taurus) Rebarrel from 45LC to 38WCF”