If you saw the other article I wrote a month ago about the TORO “Lawn” Tractor that I converted to electric, you saw that the “Operation was a success….But the patient died!”

The little “Lawn” tractor’s transmission and tiny axles could not stand up to the massive instantaneous torque of the Motenergy ME1004, 13HP, electric motor. Although the TORO originally had a 20HP gas motor, and the electric motor is rated at 13HP, you simply can not compare a gas motor’s rating in HP to an electric motor. It is suggested somewhere on the internet that it’s something like 3 or 4 to one…..Therefore, this electric motor is more like a 26-39hp motor when compared to a gas motor. And the torque curve is flat from near zero RPM to 3300 rpm…..Torque is what breaks things!..Nothing like an electric motor for pure power…Ask any TESLA owner!

So back to the subject at hand…..Now what?

Fortunately, my original plan was to convert a John Deere 214 “GARDEN” tractor to electric. But I received a gift of the TORO just as the project was starting and it was obvious to me that converting the TORO to electric would be a piece of cake as this electric motor was a near direct replacement for the gas engine. See the article here…

GARDEN tractors are much more “Heavy Duty” than LAWN tractors. The TORO had a bent sheet metal chassis, tiny transmission and little girly 3/4″ axles……The John Deere 214 GARDEN tractor weighs about 300 pounds more than the TORO, has a transaxle that looks like it came out of a Lincoln and huge axle shafts in reinforced axle housings….The steering mechanism looks like it comes out of a trailer truck…Everything about it is massive. And since it was a 40 year old John Deere tractor, it was built like a tank….And not one $%$%^&&%$# metric nut or bolt!!!!!

Apples and Oranges…

The John Deere 214 I bought for this project was perfect….as it had no motor! And it had the infinatly variable VARIATOR drive system. This system uses variable ratio pullys to allow changing the ground speed on the fly without having to change engine speed. A really neat 1970 version of a more modern Hydaulic drive system as used in most modern Garden Tractors.

Besides no motor, the tractor is in excellent condition. And the price was right at $200 with a serviceable mower deck that I’ll be selling to recoup some costs…..(See more on this later)

So lets get into the build….

I’m using all the components that were in the Toro…..Just moving them over to the JD. See the above referenced TORO article for much more detail on the WHY and HOW of this build.

But one caveat….The TORO was a 48V system. This motor can run on 48 or 36 volts….36 volts will give a bit less RPMs (3300 @ 48v VS 3000 @ 36V) and a bit less power. I’m not sure what the power figure is at 36V, but I was guessing it would be plenty based on the fact that the TORO was a monster at 48V.

Why 36V rather than 48? The TORO, with its tiny Transaxle had plenty of room under the seat for two batteries…Two 12V, Group 31 , Deep Cycle AGM batteries in the front under the hood and two under the seat…4 X 12V = 48V

But the JD with that “Lincoln” sized transaxle did not have the room. I could have put three batteries under the hood easily, but I just didn’t want that much weight on the front axle and tires. I could have welded up a bracket for a second battery BEHIND the seat, but it would have stuck out 7″ and screwed up my future plans for a Sleeve Hitch and other things back there……I figured if I went with 36V and wasn’t happy I could always add the fourth battery later.

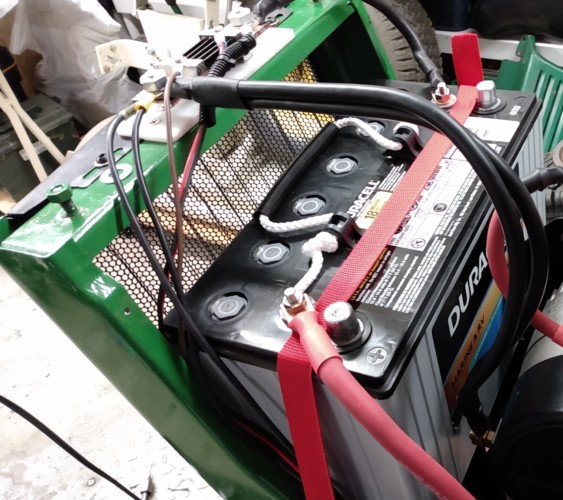

As luck would have it….The Duracell AGM batteries I’m using are about 13″ wide…..The frame rails on the JD 214 are 13.2″ inside to inside!

All I had to do was cut down the back part of the chassis about 2.5″ and weld a couple pieces of angle iron to support the battery

That was too easy! The fender pan fits right on without any modification.

Now we need to mount the motor. This will be more involved than the vertical shaft placement on the TORO. In this application the shaft needs to be horizontal.

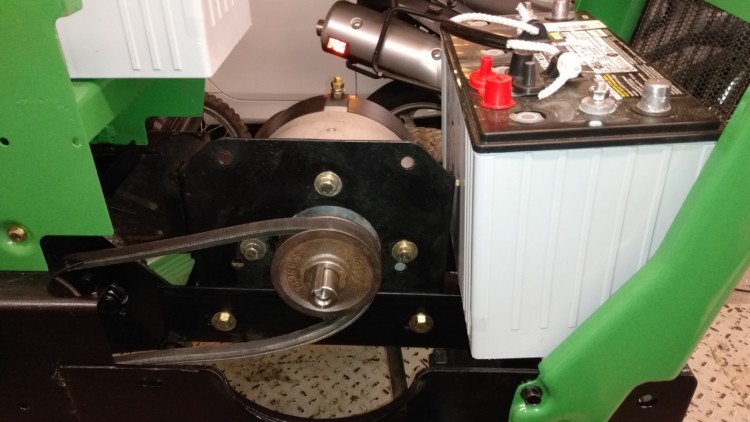

The mounting plate that I fabricated out of scrap for the TORO was used. It is 3/16″ steel with the edges turned up for more rigidity.

A couple cross supports were welded into the engine bay where the gas motor used to live. Slots were machined into this angle iron support so I could adjust the belt tension on the electric motor as needed.

The motor and its mounting plate were bolted to these supports. The rear of the motor sits on a hard rubber block for added support

A couple adjustable belt support pins were fabricated and installed. These keep the drive belt away from the pulley when the tractor is in neutral and the clutch (drive belt tensioner) is disengaged

The installation of the two front batteries was next….

The first one, up near the nose of the tractor was even easier than the rear battery. It just dropped right in place between the grill rails like it was made for it!

The second front battery would sit above the steering post and the variator system where the original, smaller, starting battery used to live. Again a support piece of angle iron was welded across to support it.

Red Nylon web battery tie downs were fabricated to keep all the batteries in place.

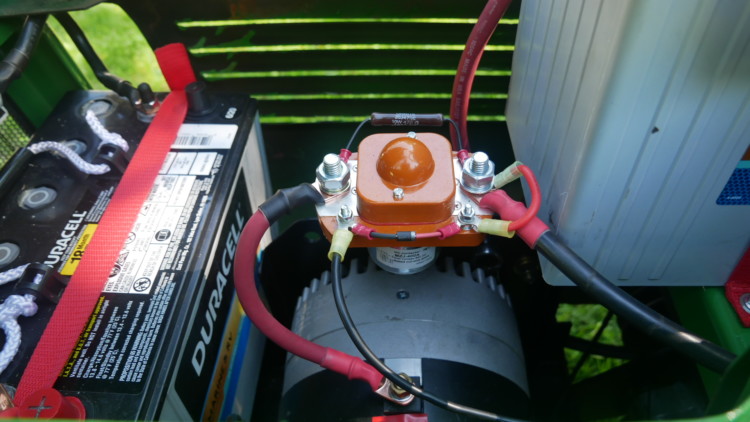

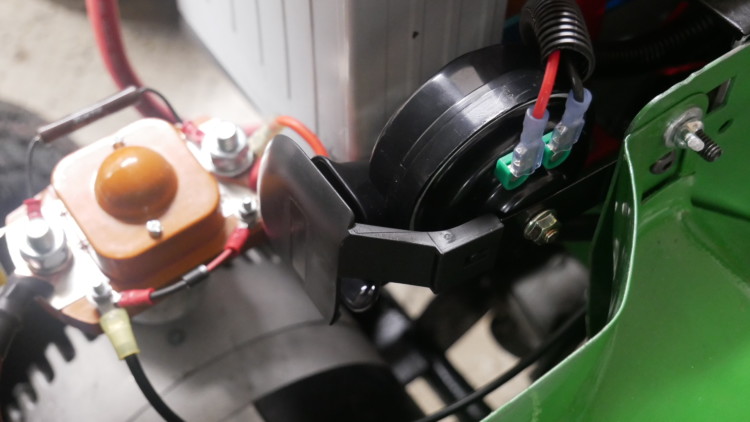

Now it was time to wire it all up. The exact same wiring schematic was used as on the TORO with the exception of only three batteries instead of four

All the components were mounted to another piece of aluminum and bolted to the side of the engine cowling with fabricated “z” brackets

The contactor was placed as close to the motor as I could to keep the battery cables short as possible

A whole new dash panel was fabricated for the battery monitor, switches for the lights, fan and even a very loud electric horn

The 500A shunt was located up front on the hood support and the headlights were rewired

Heavy Duty “ANDERSON” connectors were added to each battery for ease of charging. At the moment I don’t have a 36V charger so I have to charge each battery independently with a 12V “Smart” charger.

The hole in the rear body panel is no longer for gasoline…it is now to charge the rear battery

Here is a whole video that explains the wiring better than I can in words

So, now that it has been painted…Decaled….Re-Tired…. How does it perform?

In a word ….AMAZING!

I couldn’t be more pleased with the outcome. I’m thinking I might sell my IH Cub Cadet 782 and just stay electric…

Here are a few videos showing what it ended up as, how it drives and some of its capabilities

I get a bunch of questions from friends and neighbors:

Are you going to mount the cutting deck?…. No. I’m building a front mounted cutting deck that will have its own motors and a LiPo battery system. This will offer me the opportunity to try building a Lithium battery pack from parts. And front mounted deck will be much more manuverable on my property.

How long do the batteries last ?……. I’ve been driving this thing around for a few days. Pulling a small trailer full of firewood and dirt, letting grandkids ride it. Showing neighbors and relocating a 2000# trailer up a pretty steep hill. All totaled about two hours of use and I still show 75% battery life! I’m going to guess I can get three hours of this type of use. Now if it had the mover deck running off the tractor’s motor and battery, I estimate 45 minutes of use before batteries should be recharged.

How much did it cost ?……

John Deere 214 $200.00

BATTERIES $716.00

MAIN FUSE $ 7.49

DEADMAN SWITCH $ 13.49

CONTACTOR $ 59.18

RESISTOR $ 9.99

DIODE $ 8.99

MOTOR $606.85

DC to DC Converter $ 39.99

BATTERY MONITOR $ 30.50

FUSE PANEL $ 12.39

12V- BUSS BAR $ 1.00

IGNITION SWITCH FREE

MISC SWITCHES $ 9.70

MAIN WIRE/CONEC $ 63.25

SECONDARY WIRE $ 20.00

MISC STEEL/HDWR $ 50.00

TOTAL $1839.12

YIKES!!!! Way too much. But what the heck….This is my enjoyment. My hobby is building stuff…Most of which I really don’t need! Some folks gamble away this much in minutes! And as my friend Tom always says, “There are no ATMs in Heaven…..or Hell!â€

WHAT’S NEXT?……First a “Solar Shed” to store it in with the entire roof made of 36V / 320w solar panels and associated solar controller equipment that I picked up really cheap……To cool!

And a front mounted mowing deck that will use three 40V DC electric motors and it’s own battery system so it can be used on this tractor or the gas motor IH Cub Cadet I refurbished a couple months ago…

Here is the article on the completed front mounted mower deck

Stay tuned for updates on both of these projects….

A quick couple videos showing the John Deere Electric tractor pushing wet, heavy New England snow….Impressive!

I hope you enjoyed this article. Let me know……Be sure to check out all the other ways I waste my children’s inheritance…… www.rvbprecision.com

Pingback: John Deere 200, 210, 212, 214 Axle Seal Replacement | RVB Precision

Pingback: FRONTY MOUNTED ELECTRIC MOWER DECK FOR ELECTRIC GARDEN TRACTOR | RVB Precision